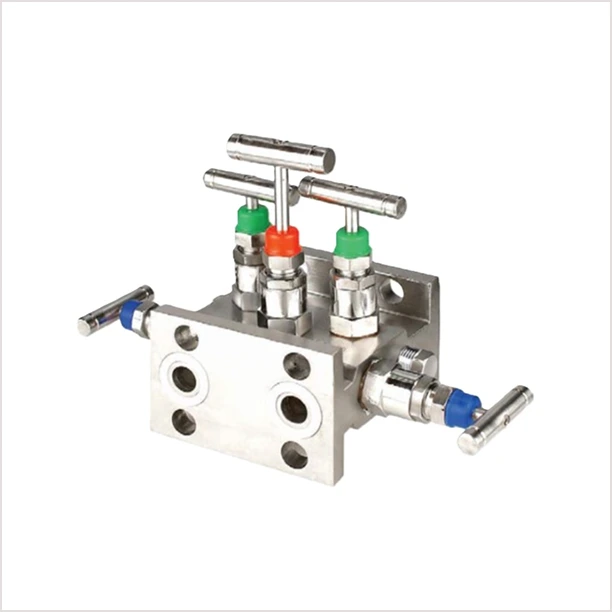

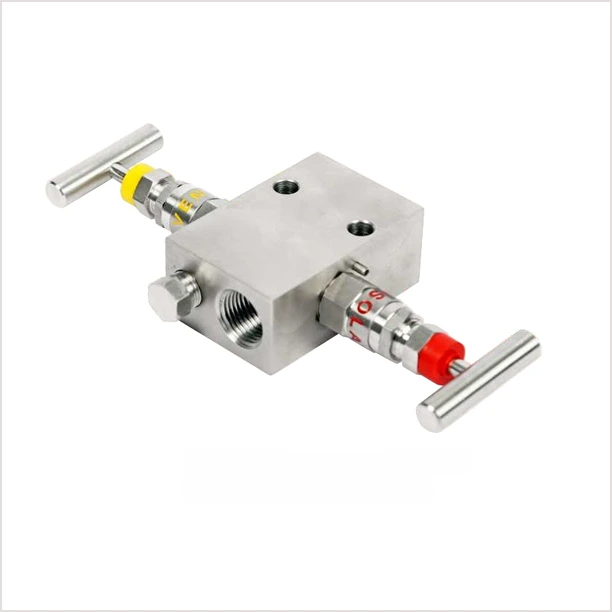

Manifold Valve

A manifold valve is a compact and efficient flow control device that integrates multiple valves into a single unit, optimizing hydraulic and pneumatic system performance. It allows for the safe isolation, equalization, and venting of pressure instruments such as pressure transmitters, gauges, and differential pressure instruments. These valves simplify piping, reduce leak points, and enhance system reliability in high-pressure applications.

Key Features

- Multi-Valve Integration: Combines multiple block, isolate, equalize, and vent functions within a single valve body, reducing installation complexity.

- Leak-Proof Sealing: Designed with high-quality seats and seals to prevent leakage, ensuring safety and efficiency.

- Compact & Space-Saving Design: Reduces piping requirements, making systems more streamlined and efficient.

- High Pressure & Temperature Resistance: Built to withstand extreme operating conditions in industrial applications.

- Corrosion-Resistant Materials: Available in stainless steel, carbon steel, and exotic alloys to handle aggressive fluids.

- Threaded, Flanged, & Compression Connections: Various end connections to suit different system requirements.

- Quick & Easy Installation: Simplifies maintenance and system modifications with fewer potential leak paths.

Common Types of Manifold Valves:

- 2-Valve Manifold: Used for pressure gauges and static pressure applications.

- 3-Valve Manifold: Ideal for differential pressure transmitters, balancing pressure between high and low sides.

- 5-Valve Manifold: Enables venting, isolation, and equalization in complex pressure measurement systems.

.webp)